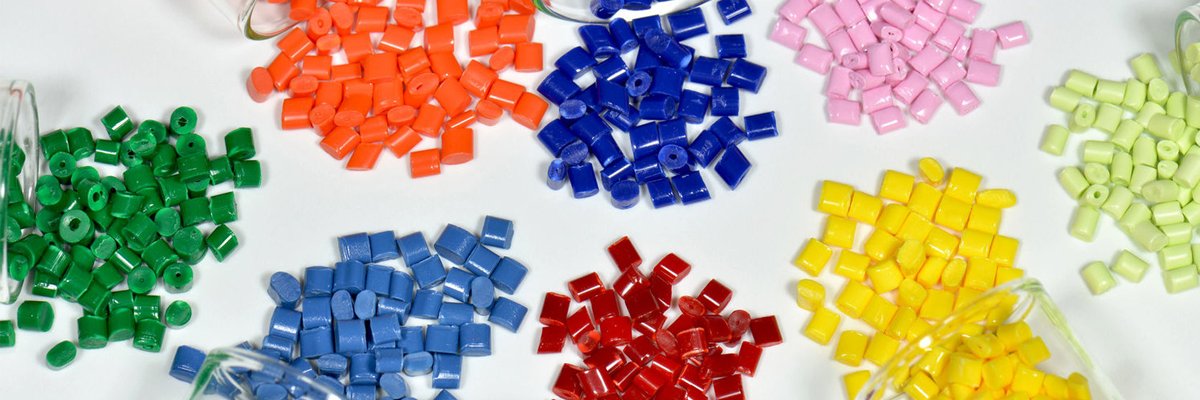

5 Common Plastic Resins Used in Injection Molding

ABS With outstanding impact and mechanical strength, ABS (Acrylonitrile Butadiene Styrene) is used in a wide range of industries and applications, from automotive to piping.

ABS With outstanding impact and mechanical strength, ABS (Acrylonitrile Butadiene Styrene) is used in a wide range of industries and applications, from automotive to piping. Metal coatings can easily adhere to this material, making it well suited for products such as desktop phones, shower heads, and handles. ABS does not have good chemical resistance, however, and should not be used in applications requiring electrical insulation or UV resistance.

Celcon (Acetal)

Celcon, a common brand name for Acetal, offers excellent surface lubricity, creep resistance (memory), and chemical solvent resistance. Ideal for food and beverage, mechanical, automotive, and household applications, this is our resin of choice for manufacturing K’NEX toy parts, as well as gears and bearings. It’s also often used in automotive applications and household appliances. It should not be used for applications in high heat environments.

Polypropylene

Polypropylene (PP) is known for its flexibility in packaging, fluid management and processing, and household goods, as well as some automotive applications. While polypropylene is flammable and vulnerable to UV radiation, it still offers good resistance to chemical solvents and electricity. Most grades of Polypropylene are flammable and degraded by UV radiation.

HIPS

High Impact Polystyrene (HIPS) provides tough, low-cost performance and highly customizable surfaces: It can be printed, glued, bonded, and decorated easily. This material is especially popular in merchandising applications and displays, printed graphics and prototypes. Although flammable, flame-retardant varieties are available.

LPDE

The most flexible version of polyethylene, LPDE, or Low-Density Polyethylene, offers moisture resistance and high impact strength. LPDE can be found in many consumer goods and housewares, as well as medical products and electronic wiring. It is difficult to bond, however, and should not be used in harsh weather or high-temperature applications.