Pin Pad Game Mould

Starting From INR – ₹1.75 Lakh | USD – $2350

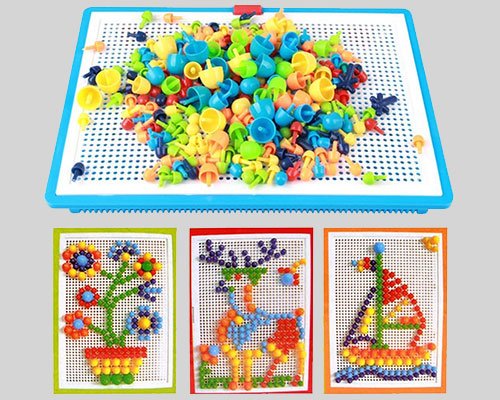

Pin Pad Game Mould

We’re the renowned manufacturer and supplier of Pin Pade Game Mould in Ahmedabad. This Pin Pad Toys Game Mold is completely customizable and we can manufacture the pin pad mould as per your requirement. This is a nice early learning educational toy set to develop children’s IQ, creativity, imagination, recognition, coordinate kids’ hands, eyes, and heads, and develop kids’ intelligence in playing. It is a lot of fun for kids to draw many figures with those cute mushroom nails such as butterflies, letters, numbers, houses, animals, plants, flowers & lot.

Our Pin Pad Toys Game Mould has the excellent quality, durability, and long life. Also, our pin pad game mold needs low maintenance.

Technical Data

| Mould Name | Pin Pad Game Mould |

| Plastic Material | PS / PP |

| Suitable Machine | 100 to 200 Tons |

| Mould Cavity Material | P-20-2738 Prehard HRC 40-42 P-20-2311 Prehard HRC 30-32 Liquid Nitrative Hardened to 48 to 50 HRL |

| Mould Life | As Per Article |

| Mould Ejector System | Ejector Pin / Stiper / Air Valve |

| Mould Cycle Time | As Per Article |

| Heat Treatment | HRC 50 |

| Mold Cold Runner | Point Gate, Side Gate, Sub Gate, Tunnel Gate, Direct Gate, etc.. |

| Gate Type | Side Gate, Sub Gate, Pin Point Gate, Edge Gate, etc.. |

| Inner package | Stretch Waterproof Film & Each Mold Painted Anti-Rust oil |

| Delievery Time | As Per Article |

| Mould Size | As Per Article |

| Mould Cavity | As Per Article |

| Mould Core Material | P-20-2738 Prehard HRC 40-42 P-20-2311 Prehard HRC 30-32 Liquid Nitrative Hardened to 48 to 50 HRL |

| Back Plate Material | Back Plate C-45 Prehard HRC 25-30 Back Plate EN-31 Prehard HRC 25-30 |

| Mould Running | Automatic / Manual |

| Mould Runner | Hot Runner / Cold Runner |

| Mould Surface Treatment | Polish, Chrome, Nitriding |

| Mold Hot Runner | Tip Type, Screw Type, Manifold Type, etc. |

| Mold Cooling System | Water Cooling |

| Mould Finish | Anti Corrosive Color Coated, Diamond Polished |

| OuterPackaging | Standard Export Wooden Case |

| Supply Ability | As Per Article |

Technical Data

| Mould Name | Plastic Block Game Mould |

| Plastic Material | PS / PP |

| Suitable Machine | 100 to 200 Tons |

| Mould Cavity Material | P-20-2738 Prehard HRC 40-42 P-20-2311 Prehard HRC 30-32 Liquid Nitrative Hardened to 48 to 50 HRL |

| Mould Life | As Per Article |

| Mould Ejector System | Ejector Pin / Stiper / Air Valve |

| Mould Cycle Time | As Per Article |

| Heat Treatment | HRC 50 |

| Mold Cold Runner | Point Gate, Side Gate, Sub Gate, Tunnel Gate, Direct Gate, etc.. |

| Gate Type | Side Gate, Sub Gate, Pin Point Gate, Edge Gate, etc.. |

| Inner package | Stretch Waterproof Film & Each Mold Painted Anti-Rust oil |

| Delievery Time | As Per Article |

| Mould Size | As Per Article |

| Mould Cavity | As Per Article |

| Mould Core Material | P-20-2738 Prehard HRC 40-42 P-20-2311 Prehard HRC 30-32 Liquid Nitrative Hardened to 48 to 50 HRL |

| Back Plate Material | Back Plate C-45 Prehard HRC 25-30 Back Plate EN-31 Prehard HRC 25-30 |

| Mould Running | Automatic / Manual |

| Mould Runner | Hot Runner / Cold Runner |

| Mould Surface Treatment | Polish, Chrome, Nitriding |

| Mold Hot Runner | Tip Type, Screw Type, Manifold Type, etc. |

| Mold Cooling System | Water Cooling |

| Mould Finish | Anti Corrosive Color Coated, Diamond Polished |

| OuterPackaging | Standard Export Wooden Case |

| Supply Ability | As Per Article |

Key Benefits

Precisely Engineered

Using the advanced machinery and highly skilled experts who have a decade of experience will precisely design and do machining of this mould.

Anti Corrosive

We use high-grade stainless steel and other premium quality material to manufacture this mould, which has a characteristic of anti-corrosive, high hardness, etc.

Long Operational Life

The design of this mould makes it unique because at the time of designing we consider all the possibilities, that’s why the overall operation life of this mould is long.

High Compressive Strength

Due to the material (stainless and steel and similar) used in the manufacturing of this mould, the compressive strength of this mould is high.

Dimensionally Accurate

The precision is the most important factor and we have a dedicated experts who check the dimension and precision of the mould at every individual step of manufacturing.

Assured Quality

We implement a quality control system whose watchwords never accept, produce or deliver faulty products & preserve a level of quality.

Durable Material

We use high-quality materials, like Aluminum and steel to manufacture the mould, that’s why the durability of this mould is also good.

Low Maintenance

This mould has a long life and also it needs a low maintenance, just follow our cleaning instructions.

- Pin Pad Game Mold

- Pin Pad Game Die

- Pin Mould

- Pin Pad Game Mold

- Pin Pad Game Injection Mould

- Pin Pad Toy Mould

- Pin Pad Block Mould

- Plastic Pin Pad Game Mould

- Pin Pad Toys Game Mould

- Pipe Block Toy Injection Die

- Pin Pad Block Game Mould

- Pin Pad Mold Exporter In India

- Pin Pad Die Maker In Ahmedabad

- Plastic Pin Pad Toys Mould

- Pin Pad Game Mold Manufacturer

- Kids Pin Pad Game Mould

- Top Pin Pad Game Die Supplier In Gujarat

- Pin Pad Toy Die

- Pin Pad Toy Injection Mold

- Pin Pad Injection Mold DIe

- Pin Art Game Mould

- Pin Pad Game Mould Manufacturer

- Pin Pad Game Mould Exporter

- Pin Pad Game Mould Supplier

- Pad Game Mould

- Pin Game Mould

- Pin Pad Mould Manufacturer

- Game Pin Mould

- Game Mould

- Pad Mould Maker

- Plastic Block Game Mould

- Pin Pad Game Mould

- Plastic Toy Car Mould

- Plastic Puzzle Game Mould

- Plastic Baby Kitchen Set Mould

- Plastic Pipe Block Mould

- Plastic Bowling Game Mould

- Plastic Table Tennis Ball & Racket Mould

- Plastic Stacking Ring Mould

- Plastic Bat & Ball Mould