The Whole Process of Plastic Injection Molding

Introduction:

Plastic injection moulding is a widely used manufacturing process that plays a crucial role in the production of a vast range of plastic products. Understanding the intricacies of this process is essential for both manufacturers and consumers.

- Designing the Mould: The first step in plastic injection molding is the creation of a well-designed mould. R.D. Mould & Industry excels in this aspect, employing skilled designers and engineers to develop molds that meet precise specifications. These molds determine the shape, size, and features of the final plastic product.

- Material Selection: Choosing the right material for injection molding is crucial. Factors such as durability, flexibility, and temperature resistance are carefully considered. R.D. Mould & Industry ensures that the selected material aligns with the desired properties of the end product, resulting in optimal performance and quality.

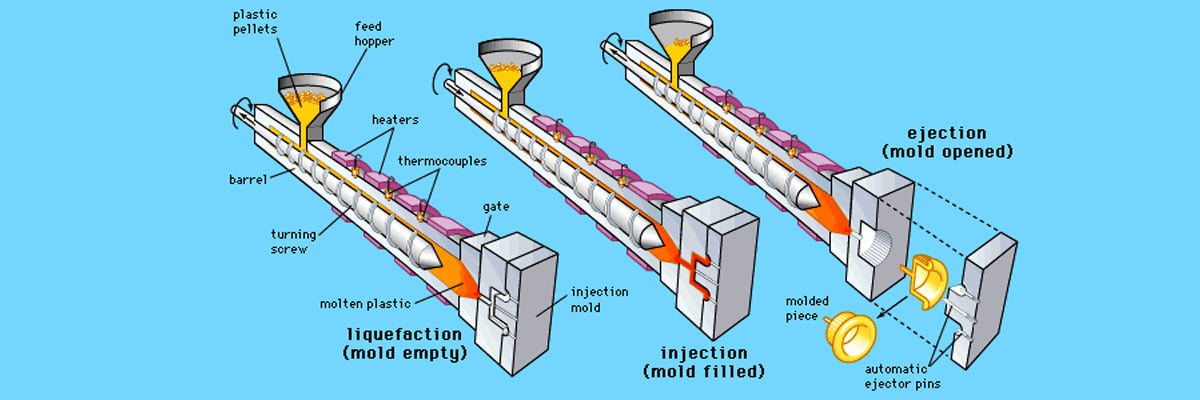

- Injection Molding Process: Once the mould and material are ready, the plastic injection molding process begins. The material is heated to a molten state and injected into the mold cavity under high pressure. This stage requires precision and expertise to ensure the material fills the mold completely, resulting in a defect-free product.

- Cooling and Ejection: After the molten plastic has been injected into the mold, it undergoes a cooling process to solidify and take the desired shape. R.D. Mould & Industry employs advanced cooling techniques to optimize cycle times and enhance productivity. Once the plastic has solidified, the mould is opened, and the newly formed product is ejected.

- Finishing Touches: After ejection, the plastic product may undergo additional processes, such as trimming excess material, surface finishing, or adding specific details. R.D. Mould & Industry pays meticulous attention to these finishing touches, ensuring the product meets the highest standards of quality and aesthetics.

- Quality Assurance: Maintaining quality is paramount throughout the plastic injection molding process. R.D. Mould & Industry adheres to rigorous quality control measures, conducting inspections, and tests at each stage. This ensures that every product leaving their facility is defect-free, reliable, and meets the client's specifications.

- Conclusion

Plastic injection molding is a complex process that requires expertise, precision, and attention to detail. R.D. Mould & Industry excels in every stage of this process, from mold design to quality assurance.We manufacture various types of houseware molds including Plastic Dry Fruit Box Mould, Lead Type Multipurpose Plastic Storage Container Mould, Plastic Lunch Box Mould, and Plastic Pencil Box Mould, Multipurpose Plastic Storage Container Mould, Plastic Jewelry Box Mould, Plastic Ice Cream Box & Cup Mould, Plastic Khajoor Box Mould, etc. Best quality houseware mould exporter from India.